Aluminum die casting and plastic mold blog

ALUMINUM DIE CASTING & PLASTIC MOLD

Magnesium Alloys: Properties, Applications, and Surface Treatments

Magnesium alloys are widely recognized for their lightweight properties, high strength-to-weight ratio, and excellent machinability. As one of the lightest structural metals, magnesium is often alloyed with other elements such as aluminum, zinc, manganese, and rare...

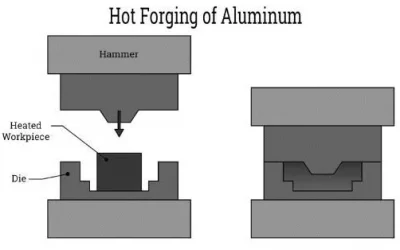

Hot Forging Aluminum: Process, Benefits, and Applications

Hot forging aluminum is a critical manufacturing process used to produce high-strength, durable, and lightweight components for various industries. This technique involves heating aluminum to a specific temperature, making it more malleable before applying...

The Advancements and Applications of Zinc Casting

Zinc casting has become an essential process in modern manufacturing, providing a cost-effective solution for producing high-precision metal components. With its excellent casting properties, high strength, and superior surface finish, zinc is widely used in...

Plastic Injection Molding Companies in California

California is home to a thriving plastic injection molding industry, driven by the state’s diverse economic landscape, innovative culture, and proximity to global markets. The state’s plastic injection molding companies serve a wide range of industries, including...

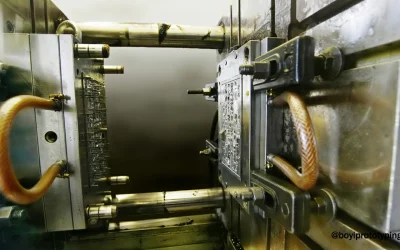

Cold Runner Mold and Injection Molding: A Comprehensive Guide

Injection molding is a popular manufacturing process used to produce high volumes of identical parts. One of the critical components of injection molding is the runner system, which is responsible for channeling the molten material from the injection molding machine...

The Evolution of Large Part Injection Molding in Modern Manufacturing

The demand for large part injection molding has grown significantly as industries continue to develop bigger, more complex, and durable plastic components. Manufacturers are increasingly relying on injection molding large parts to produce high-quality, lightweight,...

The Significance of Plastic Stool Moulds in Modern Manufacturing

Plastic stool moulds are critical tools in the production of moulded plastic stools, which are widely used in homes, offices, schools, and commercial spaces. These moulds enable manufacturers to create stools that are not only functional but also visually appealing,...

TPE Materials: Understanding Their Versatility and Applications

Thermoplastic Elastomers (TPE) are a class of materials that offer a unique combination of the characteristics of rubber and plastics. This blend of properties makes TPE materials indispensable in a wide range of applications, from automotive components to medical...

Is ABS Plastic Safe? An In-Depth Analysis of Its Safety and Uses

Acrylonitrile Butadiene Styrene (ABS) plastic is one of the most commonly used thermoplastic polymers in modern manufacturing. Known for its toughness, impact resistance, and glossy finish, ABS plastic is widely employed in various industries, including automotive,...

Registration

Get Early Bird Tickets!

Ac feugiat ante. Donec ultricies lobortis eros, nec auctor nisl semper ultricies. Aliquam sodales nulla dolor. Fermentum nulla non justo aliquet, quis vehicula quam consequat duis ut hendrerit.